AI Enabled Cameras for Quality Inspection: Steel Manufacturing

Challenge

The sinter plant faces a significant issue with the oversize material escaping through damaged or worn screen mats during the sintering process. This leads to larger particles being transported via conveyors such as BC-22, BC-23, P-2-1, and CF-9, which are designed for finer materials. These oversized particles cause frequent blockages and jamming in the downstream chutes, disrupting the smooth flow of materials. If left unchecked, this can result in operational delays, decreased efficiency, and potential equipment damage, making timely detection and resolution of screen mat failures crucial to maintaining productivity.

Solution

Implementing high-resolution intelligent cameras powered by AI can provide real-time monitoring and early detection of oversize materials on critical conveyors. By identifying larger particles escaping through damaged screen mats, the system can trigger timely alerts, allowing operators to take corrective action before blockages occur.

Outcome

Implementing AI-powered intelligent cameras for early detection of oversized materials will significantly reduce delays caused by chute jamming, improving material flow and operational efficiency. Just-in-time screen repairs will lower maintenance costs and extend equipment life. This solution boosts plant productivity, ensures consistent sinter size for optimal blast furnace performance, and enhances safety by minimizing unplanned stoppages and manual interventions.

Approach

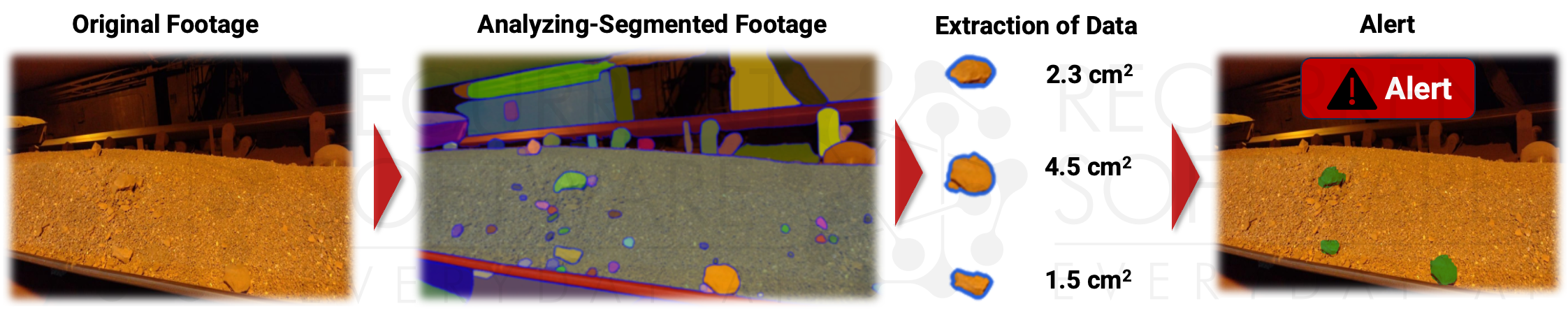

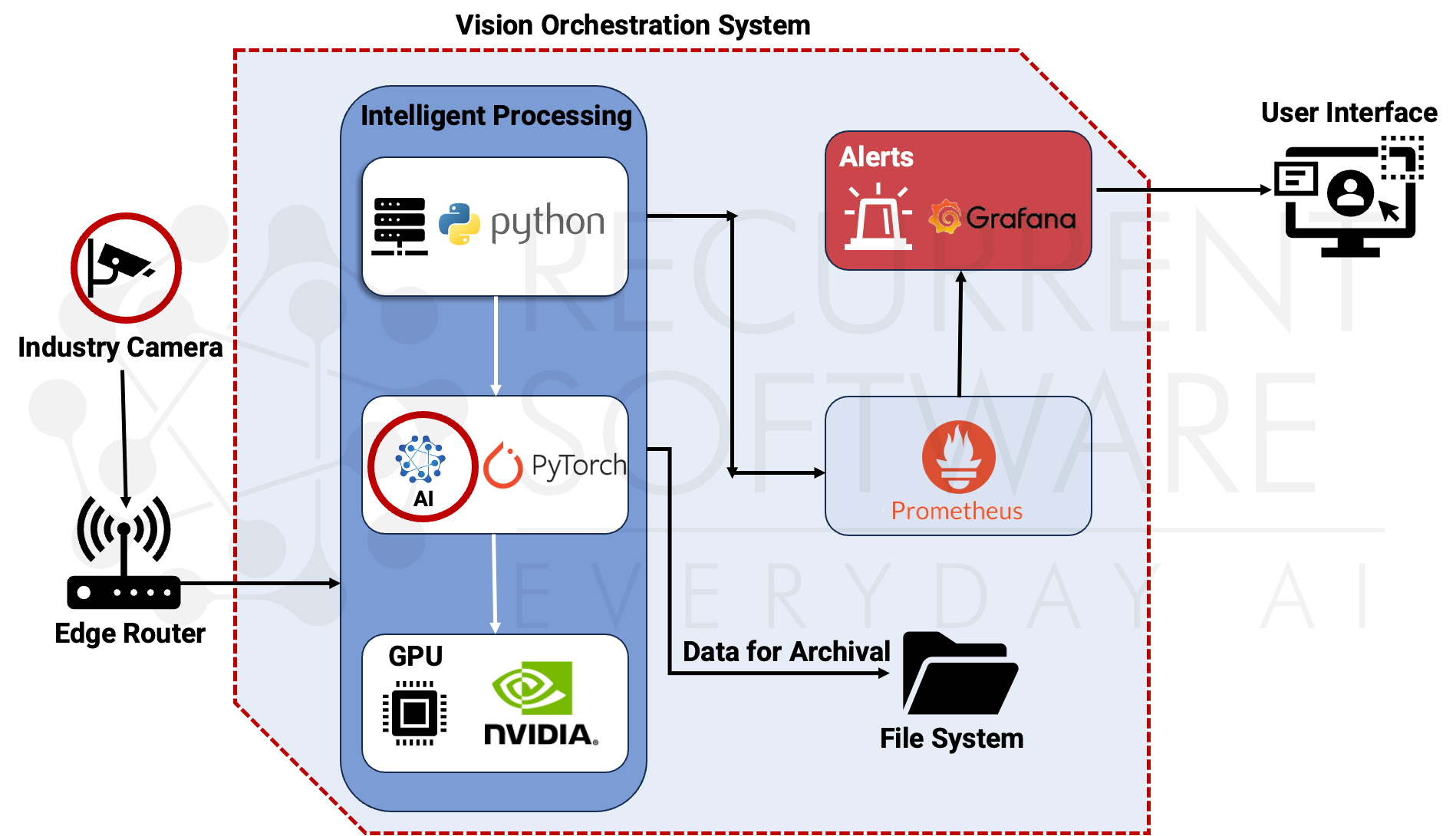

The solution utilizes a Vision Orchestration platform to observe data from live video feeds provided by industrial cameras via an edge router. This setup allows for real-time monitoring of conveyor belts and sinter material flows. The video feed is processed to segment the image into different components, specifically identifying oversized particles. Image processing techniques are used to calculate the area of each particle, helping in differentiating between acceptable sinter material and oversize particles. The calculated data is then stored in a time series database, Prometheus, for historical analysis and generating trends. The system is also integrated with an alert mechanism to notify operators immediately when oversize material is detected, enabling timely action. This proactive approach prevents material blockages in downstream processes, thereby maintaining a smooth workflow and reducing downtime.

Technology

High-Resolution Dust-Resistant Cameras:

Industrial-grade, dust-resistant cameras are used to capture real-time footage of conveyor belts. These cameras are designed to handle rugged environments and are placed strategically to monitor critical sections.

Segmentation Model (SAM):

SAM (Segment Anything Model) is leveraged for precise segmentation of sinter particles and accurate measurement of their dimensions, ensuring that only correctly sized particles are conveyed in real time, which enhances the efficiency and responsiveness of the entire process.

Time Series Database (Prometheus):

The processed data, including area measurements and detection events, is stored in Prometheus. This allows for historical analysis, anomaly trend tracking, and predictive maintenance insights.

Alerting System (Grafana):

When the system detects oversized particles, alerts are triggered in real time based on configurable rules. These alerts are relayed to the control room operators via Grafana, allowing for easy configuration and visualization. This enables them to take immediate corrective actions before further operational disruptions occur.

Technical Landscape

Talk to our Expert

Connect with our experts for tailored AI solutions that drive innovation and efficiency. How can we help?

Let'sdiscuss a solutionfor you